Getting The Roberts Prototype Machining Company Profile - Dun To Work

The Multi-Axis CNC Machining Facility - CIMtech Mfg Inc PDFs

Additionally, using digital 3D styles permits quick and exact modifications. If a machined prototype displays a physical defect arising from bad design, the engineer can return to the CAD software application to make ideal modifications for the next model. Various variations can be compared side by side, and simulation software application can even be utilized to preemptively check how a part will perform in the real life.

CNC Machining Services - CNC Parts - CNC Prototyping - Premium Parts

CNC Machining Service - CNC Milling Service - AN-PROTOTYPE

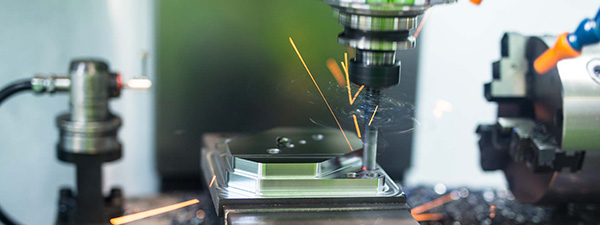

While many prototyping procedures count on human skill (and are for that reason prone to human mistake), CNC devices follow their directions to within a portion of a millimeter. Notably, they can also do it over and over again. Although Full Article may only be making a single model, a CNC machine can, if needed, run the very same job a 2nd time with minimal discrepancy from the very first.

(Manual processes are extremely essential, but it's simpler to ensure consistency with an automated device.)If a prototype does not have a mechanical function, it might be suitable for 3D printing, which although not known for producing high-strength parts costs extremely little and can be performed in a brief area of time.

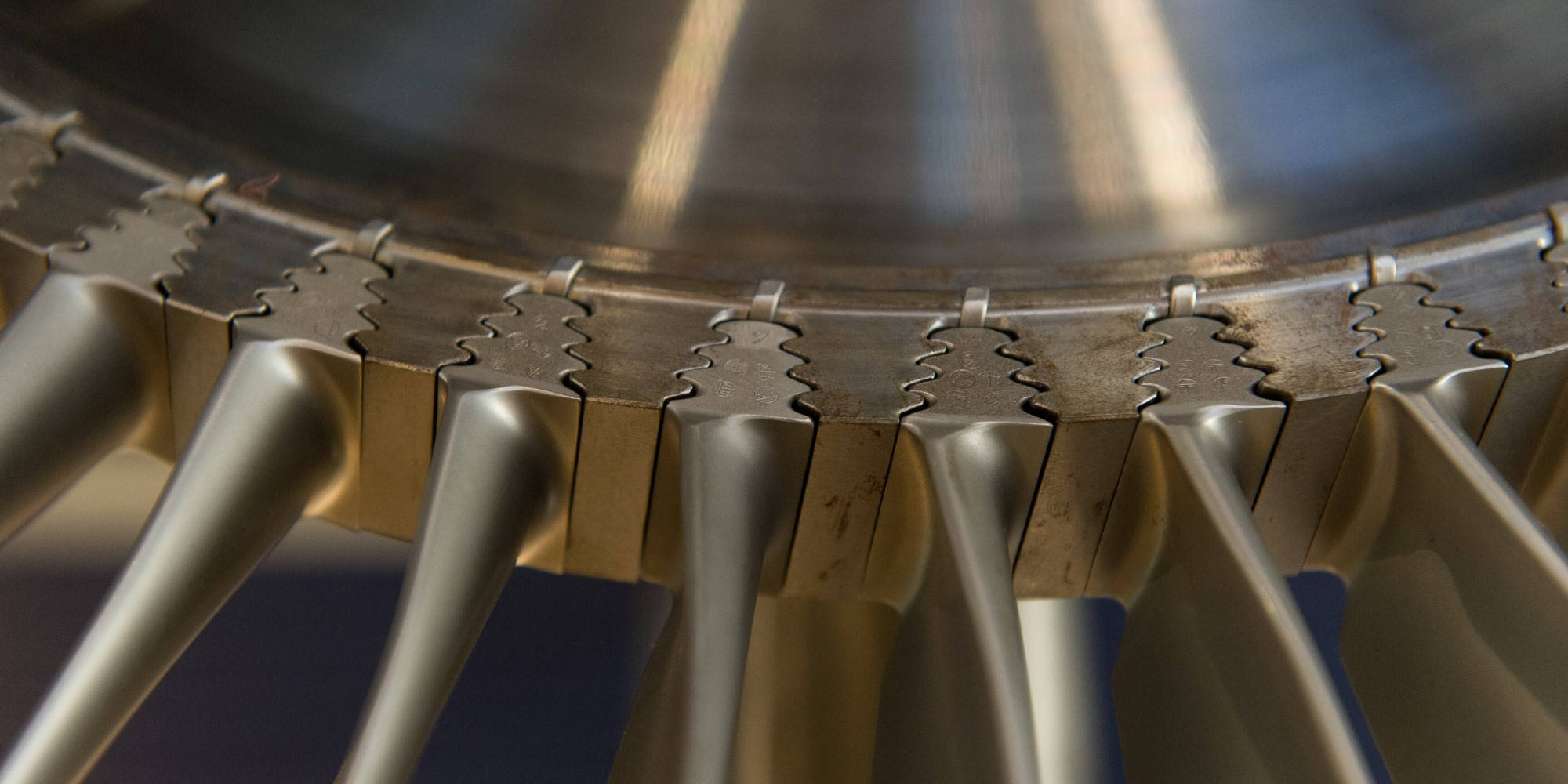

CNC machining not only uses a vast array of compatible materials, it also uses some incredibly strong and resilient ones, consisting of a large range of metals. It is possible to 3D print with metals also, however not with a low-priced FDM printer. Common CNC machining products include: Aluminum, ABSSteel, PCStainless Steel, PPMagnesium, PSTitanium, POMZinc, PMMABrass, PAGF30Bronze, PCGF30Copper, Teflon, LDPEHDPEAnother significant advantage of using CNC machining for models is the ability to create models similar to the last part.

Some Known Incorrect Statements About To Find the Optimal Prototyping Method, Ask the Right

Part of this is down to products. Numerous engineering metals are extremely machinable, which permits engineers to make prototypes from the same (or comparable) materials they will utilize for the last part. But the quality of the procedure itself is likewise an aspect: machined parts are strong and do not show weakness along certain axes like printed parts, while the machining procedure itself can even be utilized to reproduce other procedures like sheet metal forming.

Regardless of its benefits, CNC machining has certain constraints as a prototyping method, which might lead businesses to favor an alternative approach. Among the obvious drawbacks of CNC machining prototypes is the cost of the procedure. Machining centers are big pieces of equipment that need significant power and higher human guidance than 3D printers.